contact details

Vision / Measurement & control / Components and equipment / CNC

presentation / know-how

For over 20 years, VISIO NERF has been designing and building modular

image processing systems for quality control and camera-guided robots

for industrial production of all kinds.

Today, 30% of our collaborators work in research and development,

a domain in which VISIO NERF invests 15% of its annual revenue.

The result of this constant innovation is a range of vision sensors

achieving unrivalled levels of accuracy and reliability and catering

for the most widespread industrial functions (quality control,

robot guidance, quality sorting, and so on) – from the simplest

to the most complex.”

Click on the icon to download the document in PDF for this company.

for more information on :

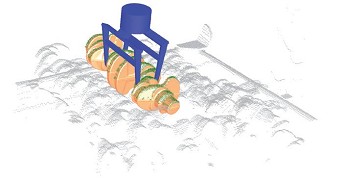

EYESBERG 3D by Visio Nerf

VISIO NERF offers you a range of solutions called

EYESBERG 3D, based on tested and reliable technology.

The underlying principle involves comparing a 3D

point cloud, acquired in real time by a vision sensor,

with the part’s CAD model. Scanning a small part of the

component – like the tip of an iceberg – is enough for the

software to identify and locate the part in the working

environment.

We offer to our clients an easy to use and standard

software package. The only thing they need to add is

their CAD file of the part.

Several modules may be combined for use with a

single vision sensor (e.g. identification plus guiding or

identification plus measurement). This enables complex

problems to be addressed using standard tools.

These solutions have been long sought after in many

industrial sectors (aeronautics, automobile, rail …)

because they provide better quality control (EYESBERG

3D in-line measurement) and increased productivity.

Version française

With the support of Symop – the French Association for manufacturing Technologies - Privacy policy

Version française

With the support of Symop – the French Association for manufacturing Technologies - Privacy policy