contact details

other manufacturing & business plants

12 automatic aluminium parts picking at oven exit (France, USA)

3 systems for automatic order preparation (intralogistics)

Several Fast and accurate 3D scan systems in various Research Labs.

Vision / Industrial robotics / Measurement & control

presentation / know-how

VIDEOMETRIC is a French engineering company created in 1999, highly skilled in 2D & 3D measuring systems & 3D reconstruction systems at very high precision.

VIDEOMETRIC systems are installed in aluminium foundries, sismeic Research labs, Building and public works companies, automobile factories and logistic centers for various « Robotized 3D bin picking » applications.

VIDEOMETRIC proprietary technology is unique as it calculates a very precise 3D position of objects, using various Image Acquisition technics (Photogrammetry, Point cloud or Fringes projections), associated with a total mastering of robotic concepts.

VIDEOMETRIC is currently looking for worldwide OEM partners and integrators of its technologies, accessible thru licencing.

Click on the icon to download the document in PDF for this company.

-

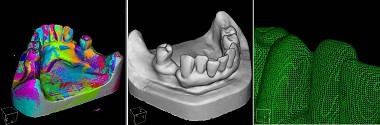

Prothesis digitization

High precision prothesis digitization

-

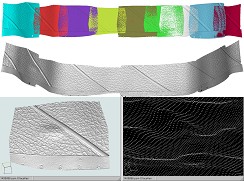

Tyre internals 3D digitization

Defects detection

-

3D movements study from 1 camera

3D movements studies from 2D movie

-

3D scanner

Digitization, reconstruction, texture mapping

-

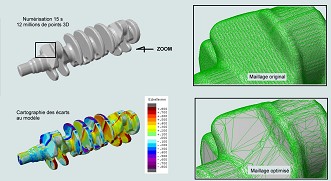

"3D shape deviation" analysis

Analysis of 3D shape deviation from CAD/CAM model

-

Production plant 3D scanning & reconstruction

3D digitization and reconstruction of interior & outside industrial volumes

-

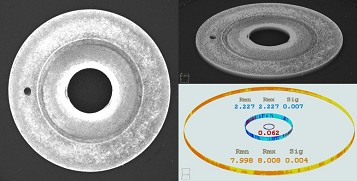

Production line 3D quality control

Part roundness analysis

-

3D digitization of industrial parts

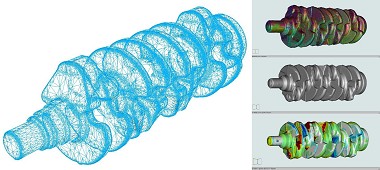

Crankshaft balancing system (Patented)

-

Body & Face 3D scanner

Face & Body 3D digitization

-

CRT 3D HANDLING

Automatic 3D handling of Cathodic Ray Tubes

-

PHARMACEUTICAL LOGISTICS

Automatic Purchase Order boxing

-

SmartPlug NG3

Aide à la connexion automatique de puissance électrique

for more information on :

Metallic bars 3D picking

This frequent production line operation is rather complex : Parts are very close from each other, and more or less shiny

Our specific 3D Vision system is grabbing accurately and quickly (Vision cycle < 2s) all parts, whatever are their length and their aspect. The lighting system is compatible with “production line” conditions.

3D industrial bin-picking

VIDEOMETRIC now offers its 3D bin picking technology, very fast an accurate. For many years, our systems drive picking robots for the automotive industry, and very recently in the logistic domain.

For example composed of a stereoscopic carbon arm, 2 Gigabit cameras and a standard video beamer (no moving part), our systems can pick up goods in less than 1 second (Vision cycle time for the most performant system today)

video :

3D distorsion factor analysis

VIDEOMETRIC now offers its 3D distorsion factor analysis technics, with very high precision results.

From just one 640x480 digital camera, able to grab images at a pace of 100 fps, the application software renders, after image registration (precision : 1/500th of a pixel), continuous object distorsions measurements with a precision of 1/100th of a pixel.

Video link :

video :

Crankshaft balancing system (Patented)

Crankshaft balancing is a mandatory operation before its mounting into automotive engines. Usually, its continuous rotation helps to determine overweighs, that will be corrected by several tooling operations.

VIDEOMETRIC digitize in 3D any kind of crankshaft at high precision and quickly. The 3D model result is analyzed, to determine the ideal tooling axis. It is now possible to estimate precisely the necessary tooling operations, and to discard a faulty crankshaft, at a very early step.

Video :

Version française

With the support of Symop – the French Association for manufacturing Technologies - Privacy policy

Version française

With the support of Symop – the French Association for manufacturing Technologies - Privacy policy